FIBER GLASS MATTING Chopped Fiber Glass Mat

P02 Powder Chopped Strand Mat is made of randomly distributed chopped E6 glass strands held together by an powder binder.

P02 is compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

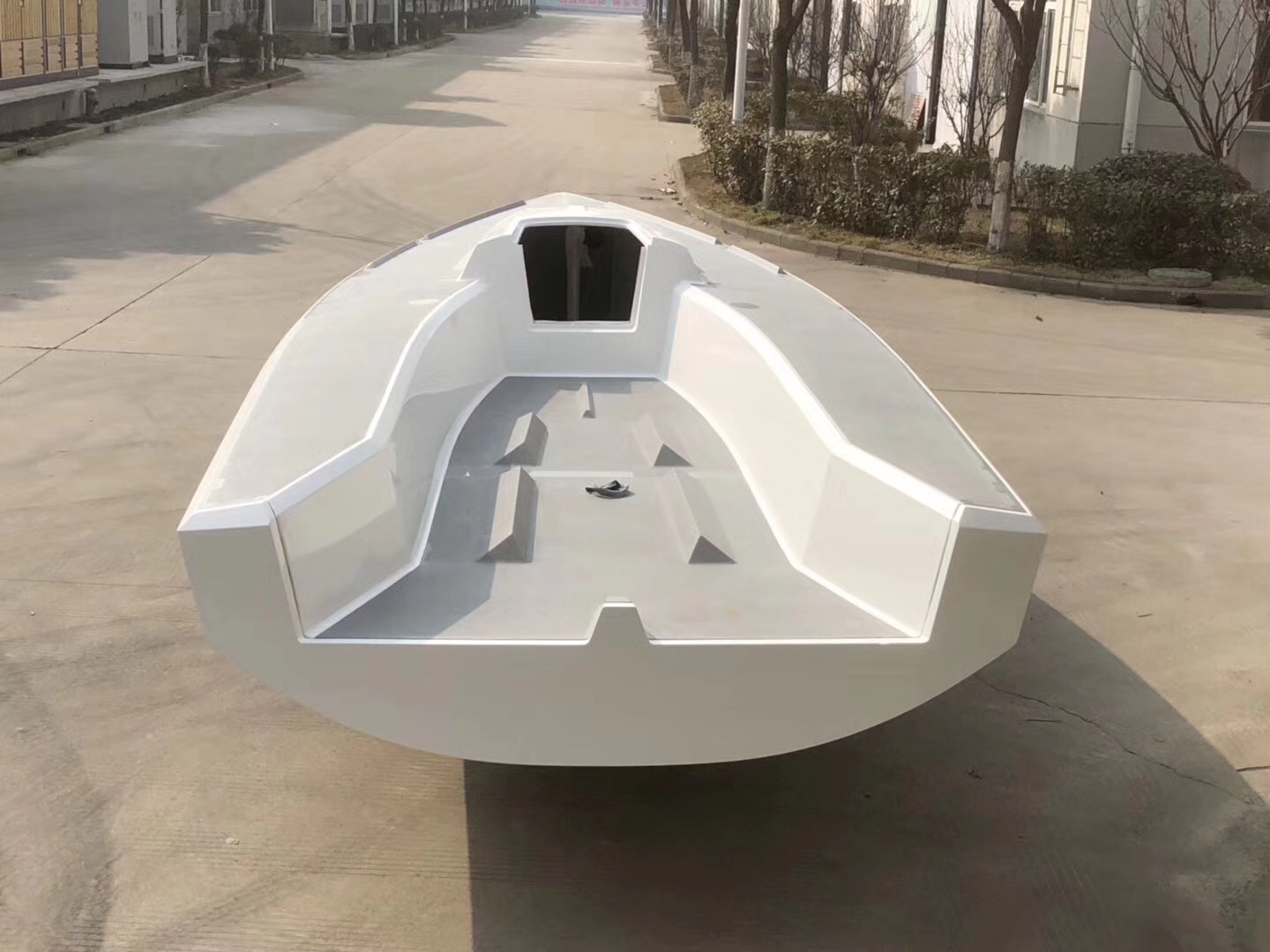

P02 is designed for use in hand lay-up, filament winding, compression molding and continuous laminating processes. Its end-use applications include boats, bath equipment, automotive parts, chemical corrosion resistant pipes, tanks, cooling towers and building components.

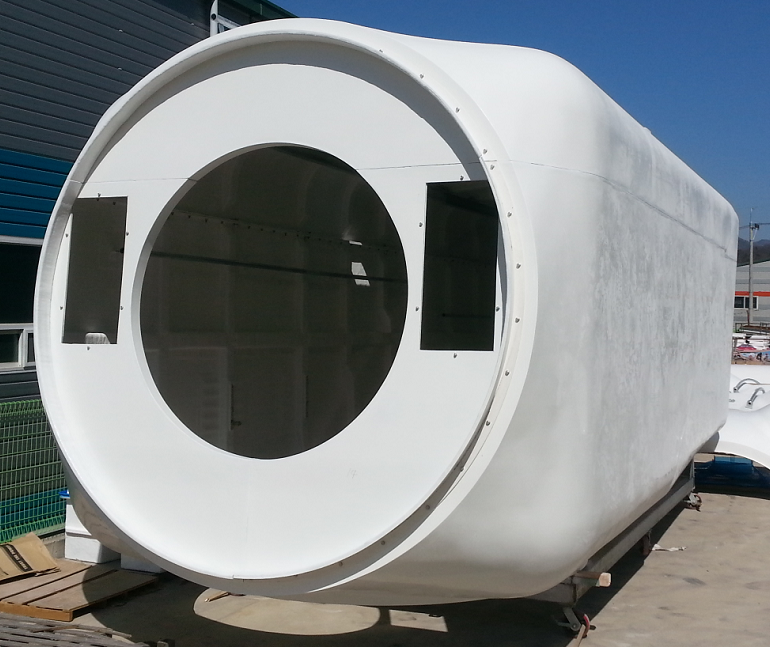

Chopped Fiber Glass Mat used in aerospace

Chopped Fiber Glass Mat used in water tanks

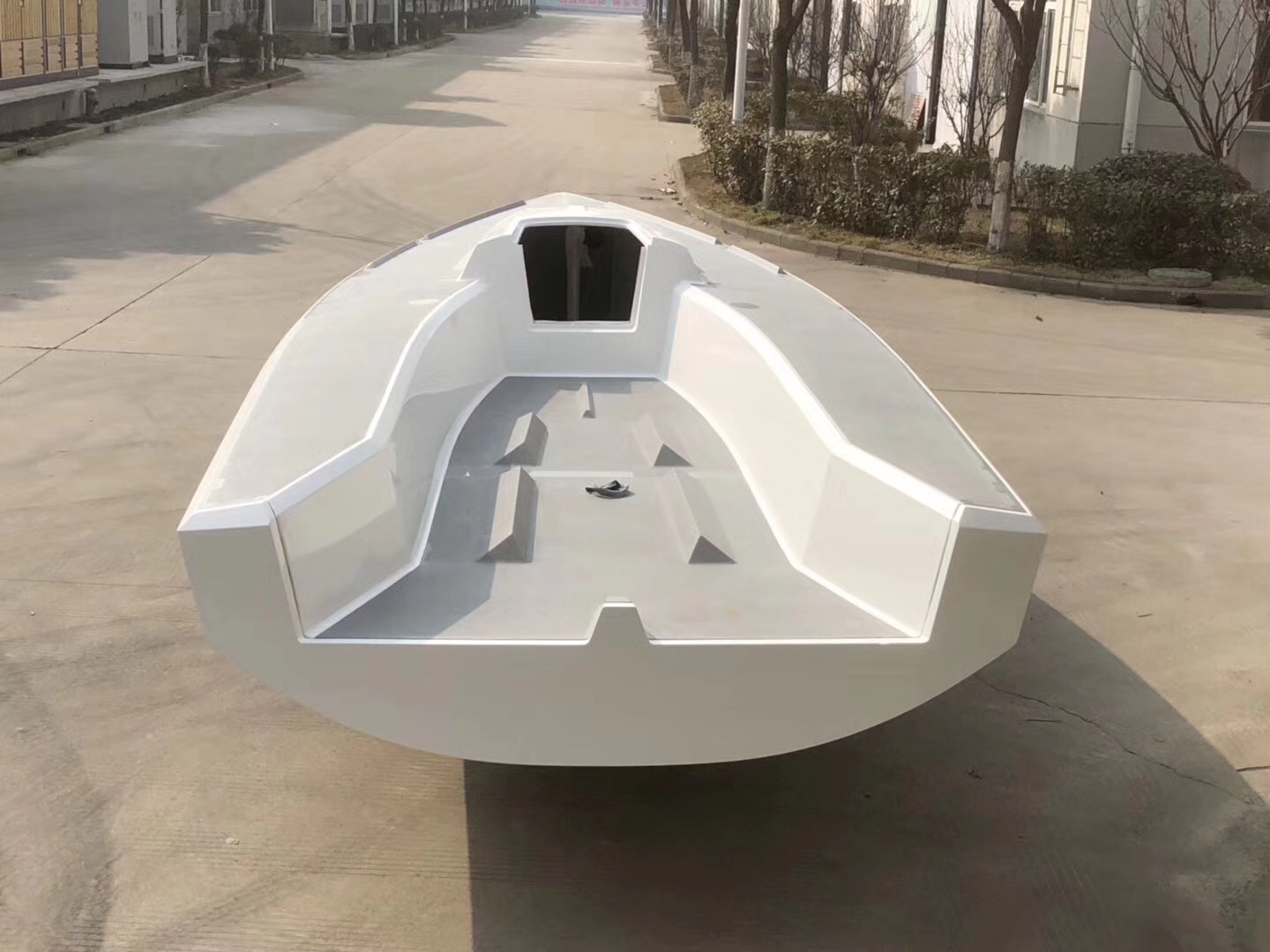

Chopped Fiber Glass Mat used in making FRP boat

Product features

High tensile strength, allowing for use in hand lay-up process to produce large-area parts.

Good wet-through and fast wet-out in resins, rapid air leas

High mechanical strength of parts Superior acid corrosion resistance

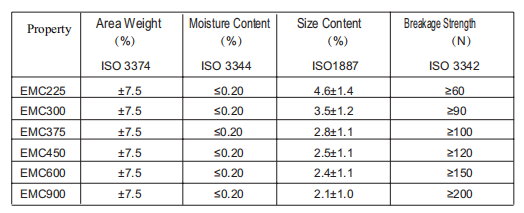

Specification

Storage

Unless otherwise specified, powder chopped strand mats should be stored in a cool, dry, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15℃ to 35℃ and 35% to 65% respectively.

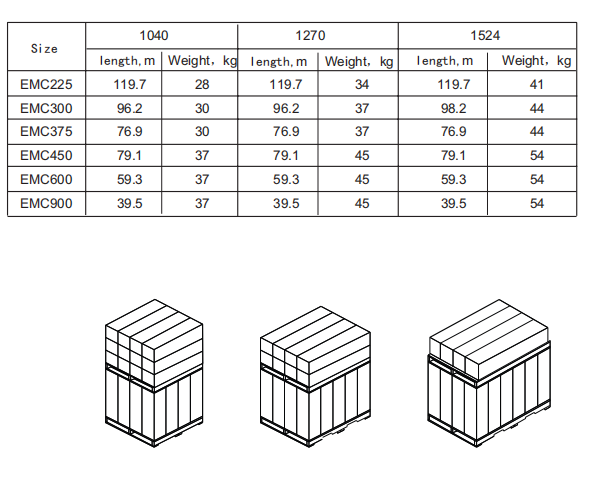

Package

Each Powder Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 90mm. The roll outside diameter is approximately 265mm. Each roll is wrapped up in plastic film and then packed in a cardboard box. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.