| Unit Price: | USD 3.3000 - 3.3800 / Others |

|---|

| Unit Price: | USD 3.3000 - 3.3800 / Others |

|---|

classification: Chemical Auxiliary Agent

CAS No.: 80-15-9

Other Names: catalyst

MF: C3h5no)n

EINECS No.: 201-254-7

Type: plastic curing agent

Usage: Plastic Auxiliary Agents

Brand Name: Trigonox

Model Number: Trigonox K-80

Product Name: Catalyst curing agent hardener

Appearance: Clear Liquid

Product Description: Catalyst curing agent hardener

Function: Catalyst curing agent hardener

Packaging: 20kg/barrel

packaging materlal: plastic barrel

Assay: 80.0-85.0%

Density, 20°C: 1.06 g/cm3

Active oxygen: 8.40-8.94%

Purity: 100%

Place of Origin: Jiangsu, China

model: Trigonox K-80

Packaging: plastic barrel

Productivity: 99999999999999999

Brand: Trigonox K80

Place of Origin: CHINA

Supply Ability: 100000 Kilogram/Kilograms per Year

Port: Shanghai Port of China

Catalyst curing agent hardener appearance

Trigonox® K-80

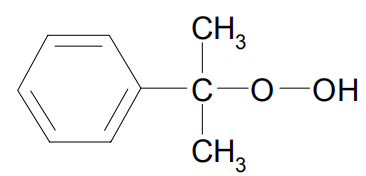

Product description Cumyl hydroperoxide, 80% in aromatic solvent mixture

CAS No. : 80-15-9

EINECS/ELINCS No. : 201-254-7

TSCA status : listed on inventory

Specifications Appearance : Clear liquid

Assay : 80.0-85.0%

Color : 450 Pt-Co max.

Active oxygen : 8.40-8.94%

Characteristics Density, 20°C : 1.06 g/cm3

Viscosity, 20°C : 10.4 mPa.s

Storage Due to the relatively unstable nature of organic peroxides a loss of quality can be detected over a period of time. To minimize the loss of quality, AkzoNobel recommends a maximum storage temperature (Ts max.) for each organic peroxide product.

For Trigonox K-80 Ts max. = 40°C and Ts min. = -30°C to prevent crystallization

When stored under these recommended storage conditions, Trigonox K- 80 will remain within the AkzoNobel specifications for a period of at least 6 months after delivery.

Thermal stability Organic peroxides are thermally unstable substances, which may

undergo self-accelerating decomposition. The lowest temperature at

which self-accelerating decomposition of a substance in the original packaging may occur is the Self-Accelerating Decomposition Temperature (SADT). The SADT is determined on the basis of the Heat Accumulation Storage Test.

For Trigonox K-80 SADT : 75°C

1 phr Trigonox K-80 90°C

1.5 phr Trigonox K-80 + 0.5 phr Acc. NL-51P 1380 min.

The following table indicates the performance of Trigonox K-80, in comparison with usual Butanox® systems, in a vinylester resin:

|

Vinylester resin |

100 |

100 |

|

Trigonox K-80 |

2 |

- |

|

Butanox LPT |

- |

2 |

|

Accelerator NL-49P |

- |

2 |

|

Accelerator NL-63-10P |

- |

2 |

|

Accelerator VN-2 |

1 |

- |

|

Gel time at 20°C (min.) |

12 |

17 |

|

Cure at 20°C in 2 mm laminate |

|

|

|

Time to achieve a Barcol hardness (934-1) of 25-30 in hours |

0.5 |

1 |

|

Residual styrene (%) after 24 hours |

4.8 |

7.1 |

|

after 1 month |

0.6 |

4.2 |

Jiangyin Thousands Chemicals Co. Copyright © All rights reserved Privacy Policy site map sitemap.html