| Unit Price: | USD 12.8500 - 12.9000 / Others |

|---|

| Unit Price: | USD 12.8500 - 12.9000 / Others |

|---|

Model No.: Perkadox® CH-50

classification: Chemical Auxiliary Agent

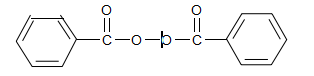

CAS No.: 94-36-0; 84-61-7

Other Names: catalyst

MF: C3h5no)n

EINECS No.: 202-327-6; 201-545-9

Type: plastic curing agent

Usage: Plastic Auxiliary Agents

Brand Name: Trigonox

Model Number: Trigonox CH-50

Product Name: Dibenzoyl peroxide powder

Appearance: White Powder

Product Description: resin catalyst

Function: resin fast cure agent

Packaging: 20kg/barrel

packaging materlal: plastic barrel

Assay: 49.0-51.0%

Bulk Density: 0.640 g/cm3 (40 lb/ft3)

Storage: under shelter

Purity: 100%

Place of Origin: Jiangsu, China

model: Trigonox CH-50

Packaging: plastic barrel

Supply Ability: 100000 Kilogram/Kilograms per Year

Port: Shanghai Port of China

Perkadox CH-50 is a free flowing fine particle powder containing 50% dicyclohexyl phthalate for curing unsaturated polyester and acrylic resins at room temperature and high temperatures. Perkadox CH-50 should be used in combination with aromatic tertiary amine accelerators at temperatures up to 80°C and no accelerators are required above 80°C.

CAS No. : 94-36-0; 84-61-7

EINECS/ELINCS No. : 202-327-6; 201-545-9

TSCA status : listed on inventory

Specifications Appearance : white free flowing powder

Assay : 49.0-51.0%

Water : 2.5% max.

Characteristics Bulk density : 0.640 g/cm3 (40 lb/ft3)

Storage Due to the relatively unstable nature of organic peroxides a loss of quality can be detected over a period of time. To minimize the loss of quality, recommends a maximum storage temperature (Ts max.) for each organic peroxide product.

For Perkadox CH-50 Ts max. = 25°C (77°F)

When stored under these recommended storage conditions, Perkadox CH-50 will remain within the AkzoNobel specifications for a period of at least one year after delivery.

Thermal stability Organic peroxides are thermally unstable substances, which may undergo self-accelerating decomposition. The lowest temperature at

which self-accelerating decomposition of a substance in the original packaging may occur is the Self-Accelerating Decomposition Temperature (SADT). The SADT is determined on the basis of the Heat Accumulation Storage Test.

For Perkadox CH-50 SADT : 55°C (131°F)

Carbon dioxide, benzene, benzoic acid, diphenyl, phenylbenzoate

In North America Perkadox CH-50 is packed in non-returnable fiber cartons of 50 lb net weight.

In other regions the standard packaging is a non-returnable cardboard box for 25 kg net.

Both packaging and transport meet the international regulations. For the availability of other packed quantities consult your AkzoNobel representative.

Perkadox CH-50 is classified as Organic peroxide type D, solid; Division 5.2; UN 3106. Safety and handling Keep containers tightly closed. Store and handle Perkadox CH-50 in a dry well-ventilated place away from sources of heat or ignition and direct sunlight. Never weigh out in the storage room.

Avoid contact with reducing agents (e.g. amines), acids, alkalis and heavy metal compounds (e.g. accelerators, driers and metal soaps).

For ambient temperature curing the following amine accelerators are available to adjust the gel time and speed of cure of the cure system based on Perkadox CH-50:

Accelerator NL-65-100 (N,N-Dimethyl-p-toluidine) for short gel times Accelerator NL-63-100 (N,N-Dimethylaniline) for medium gel times Accelerator NL-64-100 (N,N-Diethylaniline) for long gel times

Dosing Depending on working conditions, the following peroxide and accelerator dosage levels are recommended:

Perkadox CH-50 2 - 5 phr *

Amine accelerator 0.05 - 0.5 phr

Cure Characteristics In a high reactive standard orthophthalic polyester resin the following application characteristics were determined.

|

Gel times at 20°C |

|

||||||

|

UP resin |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Perkadox CH-50 |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

3.0 |

|

Accelerator NL-63-100 |

0.1 |

0.4 |

|

|

|

|

|

|

Accelerator NL-64-100 |

|

|

0.1 |

0.5 |

|

|

|

|

Accelerator NL-65-100 |

|

|

|

|

0.05 |

0.1 |

0.4 |

|

Gel time (minutes) |

22 |

6 |

160 |

20 |

20 |

5 |

1 |

The speed of cure is expressed as the time to reach a Persoz hardness of respectively 30, 60 and 120 s.

|

Persoz: |

30 |

60 |

120 s |

|

3 phr Perkadox CH-50 + 0.1 phr Acc. NL-63-100 3 phr Perkadox CH-50 + 0.4 phr Acc. NL-63-100 3 phr Perkadox CH-50 + 0.5 phr Acc. NL-64-100 |

0.5 |

0.8

0.5 |

2 h <0.5 h 1 h |

|

3 phr Perkadox CH-50 + 0.05 phr Acc. NL-65-100 3 phr Perkadox CH-50 + 0.1 phr Acc. NL-65-100 |

1 |

2.5 |

14 h 0.5 h |

|

Cure of 4 mm laminates at 20°C |

|

|

|

4 mm laminates have been made with 450 g/m2 glass chopped strand mat. The glass content in the laminates is 30% (w/w).

The following parameters were determined:

- Time-temperature curve

- Speed of cure expressed as the time to achieve a Barcol hardness (934-1) of 0-5 and 25-30 respectively.

- Residual styrene content after 24h at 20°C and a subsequent postcure of 8 h at 80°C.

Jiangyin Thousands Chemicals Co. Copyright © All rights reserved Privacy Policy site map sitemap.html