| Unit Price: | USD 4.5000 - 5.0000 / Others |

|---|

| Unit Price: | USD 4.5000 - 5.0000 / Others |

|---|

classification: Chemical Auxiliary Agent

CAS No.: 614-45-9, 614-45-9

Other Names: TBPB

MF: C3h5no)n

Type: SMC BMC process catalyst

Usage: Plastic Auxiliary Agents, unsaturated polyester resin catalyst

Brand Name: SYRGIS

Model Number: NOROX KP-925H

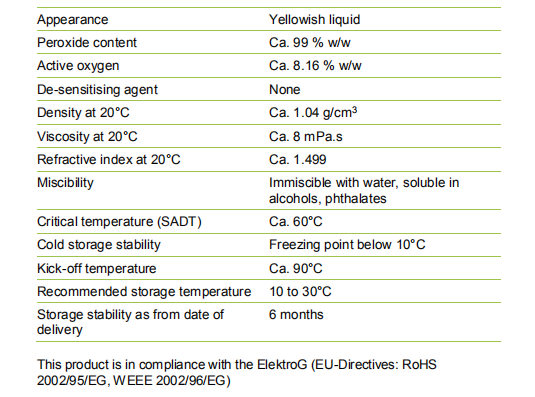

Appearance: Yellowish Liquid

Peroxide content: Ca. 99 % w/w

Active oxygen: Ca. 8.16 % w/w

De-sensitising agent: none

Density at 20°C: Ca. 1.04 g/cm3

Viscosity at 20°C: Ca. 8 mPa.s

Refractive index at 20°C: Ca. 1.499

Miscibility: Immiscible with water, soluble in alcohols, phthalates

Critical temperature (SADT): Ca. 60°C

Purity: 100%

Place of Origin: Jiangsu, China

Packaging: plastic barrel

Supply Ability: 100000 Kilogram/Kilograms per Year

Port: Shanghai Port of China

NOROX® TBPB

Tert.Butylperoxybenzoate CAS#614-45-9

Liquid, technical pure

Description

Colourless, mobile liquid, consisting of technically pure tert.butylperoxy benzoate. This aromatic perester is used as an initiator (radical source) in the curing of unsaturated polyester resins. Main application: hot press moulding of SMC or BMC at 130-160°C.

This product is in compliance with the ElektroG (EU-Directives: RoHS 2002/95/EG, WEEE 2002/96/EG)

Half-life Data

10h/1h/1min (0.1 m / benzene): 104°C / 124°C / 165°C

POLYESTER CURING:

Curing agent for UP resins. Suitable for all resin types. Temperature range: 130- 160°C. Usage level: 1-2% as supplied. "Shelf life" (gel time of resin + peroxide) several months at ambient temperature, depending on resin type. Sensitive to some fillers and pigments as well as to cobalt salts or tertiary aromatic amines. Shelf life can be prolonged considerably by adding 0.1-0.3% Inhibitor BC 500.

CURING CHARACTERISTICS:

In the range of 85-95°C ("kick-off" temperature) the curing rate is not very high, unless there is a reaction exotherm (e.g. within a heat-retaining mould). Really short cure times of 1-3 minutes can be achieved only above 120°C. The optimum temperature range for hot press moulding therefore is 130- 160°C.

PROCESSING METHODS:

Mainly hot press moulding of sheet moulding compounds (SMC) or bulk moulding compounds (BMC), as well as impregnation, dipping of wire windings.

Activity

Influence of temperature and peroxide dosage 1 on curing performance and degree of cure. Hot press moulding of 16 mm thick SMC pellets and 3 mm thick SMC sheets.

|

Temperature of mould |

130°C |

130°C |

140°C |

140°C |

150°C |

150°C |

160°C |

160°C |

|

Formulation (parts of weight) |

|

|

|

|

|

|

|

|

|

Standard SMC (resin proportion) |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Norox® TBPB |

1 |

2 |

1 |

2 |

1 |

2 |

1 |

2 |

|

Curing performance (SMC pellets) |

|

|

|

|

|

|

|

|

|

Flow time (min) |

1.50 |

1.35 |

1.15 |

1.00 |

0.95 |

0.80 |

0.75 |

0.70 |

|

Time to peak tmax (min) |

2.70 |

2.40 |

1.90 |

1.60 |

1.40 |

1.30 |

1.20 |

- |

|

Peak exotherm Tmax (°C) |

171 |

170 |

174 |

174 |

178 |

178 |

185 |

183 |

|

Degree of cure (SMC sheets2) |

|

|

|

|

|

|

|

|

|

Barcol (934) hardness |

20 |

20 |

25 |

25 |

30 |

30 |

30 |

30 |

|

Residual styrene content (%) |

2.6 |

1.7 |

0.8 |

0.6 |

0.5 |

0.2 |

<0.1 |

<0.1 |

1) The amounts added are equivalent to 1% or 2% w/w techn. pure t-butyl perbenzoate

2) The press cycles for the SMC sheets are equal to the tmax. of the corresponding SMC pellets.

Further information on suitable curing agents for unsaturated polyester resins is given in our application brochures on this subject.

Packaging

The standard packaging of Norox TBPB is 25 kg.

Jiangyin Thousands Chemicals Co. Copyright © All rights reserved Privacy Policy site map sitemap.html